An American Dream - by John Sealander

| I should have known that this trip was going to

be a bit out of the ordinary when I saw a pair of earplugs prominently

displayed alongside the usual array of soap, shampoo and shoe polish rags

near the bathroom sink. It was still dark and the alarm clock near the

bed said 5:30AM, but I could tell from the increasing activity outside

my motelroom window that it was already time to go to work.

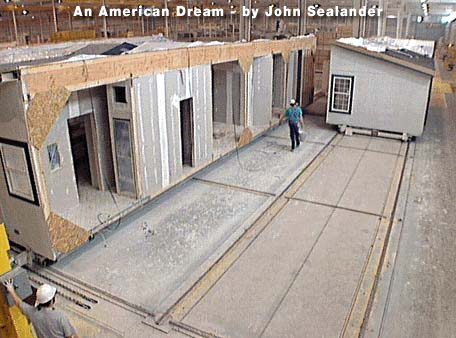

L ess than an hour later, I realized that my

definition of work might not be shared by those around me. We were filming

people working, but it was questionable in this context whether we were

actually working ourselves. From a bright yellow catwalk high above

the factory floor, I felt a bit like Dante, getting his first look at

the nine circles of the damned. In this latter-day inferno, an orchestra

of power saws, pneumatic hammers and acetylene torches competed for

our attention as we watched entire houses move through a permanent cloud

of dust on an oversized assembly line that defied the imagination. Endless

truckloads of lumber, carpet, bathroom fixtures, insulation, shingles

O ur "Vergil" for this journey through hell was an affable man named Mike. He used to drive an eighteen-wheeler, but took a job at the factory after he lost control of his truck on an icy hill and the load he was pulling came crashing through the cab. He told me that in these situations you make a dive for the floor of the truck, grab hold of the gearshift lever and hope for the best. Even though the factory was noisy, dusty and filled with machines that could turn you into compost in seconds, it represented safety and security to Mike. It didn't seem to matter to Mike that the plant was non-union and he was making less than half of what a Detroit autoworker typically took home. He liked his job. M ike was not alone. Almost everyone in the plant liked their job. It appeared that most of them were glad to have jobs, period. The spotted owl, clear-cutting regulations and a soft housing market had effectively demolished the logging industry in this part of Oregon. The employees in this small-town factory didn't look at paint fumes as a precursor to cancer, they saw them as a promise of steady employment. I'll have to admit this attitude took a bit of getting used to. I am surrounded by people who get so stressed out by airplane meals and conference calls, they go into therapy. I wonder how they'd react to an environment like this, where a stray steel cable can cut off your head. W ork is a strange concept. I stare at the ceiling

a lot. I don't get dirty. On a good day I might fill four sheets of

paper with a few words. For this, I make five times what the painters

and welders on the floor below me earn. It doesn't stop here however.

In the whole scheme of things, I am not that far removed from blue coller

status myself. I just happen to weld words together. I realize the real

money is made by people who do nothing tangible at all. If you are in

a position to have other people do your bidding for you, you will always

earn more than those who actually do the work themselves. I am not entirely

comfortable with this fact of life. For years I have admired self-sufficiency

and craftsmanship. Even in the regimented world below me, there are

visible signs of craftsmanship. I feel an affinity for the craftsmen

who skillfully use a battalion of routers, band saws and nail guns to

bring someone S omewhere in a well-lit room far from this dust-filled factory is a person who makes more in a day than the craftsmen below make in a month. He don't hammer or nail things together. He don't paint and spackle. His particular skill is in knowing that if you build a factory like this in the right part of the country, there will be hundreds of people falling all over themselves to work for next to nothing. And furthermore, these same people will stand in line to buy your product. The semi-skilled and often unemployed workers who applied for and received jobs and training at this factory may be happy. But nearby, I suspect there are a growing number of experienced housing contractors who may be out of a job as a result. In this part of the world, one in four new homes is spit out of a factory very similar to the one we are visiting. People who have never heard of Robert Venturi or Marcel Breuer love these instant houses. They are inexpensive. They are filled with gaudy bathrooms and the latest appliances. They are designed to make an elitist cry. I n a "showroom" just south of Tacoma, enthusiastic salesmen with big red umbrellas escort prospective buyers through the rain to view an entire village of innocuous factory-built domiciles. Customers nod favorably as they are shown wetbars, entertainment centers and oval shaped tubs. They get excited when they discover that there is a special nitch in the living room build to accomodate a big-screen TV. Standardization and cookie cutter designs are not a detriment to these people. They have no more use for a custom home than they would for a hand-built car. For some reason, none of these customers seem to care that their future dream home looks virtually identical to its neighbor and that none of the houses on display have any eaves. I ronically, I am making an infomercial to sell even more of these manufactured homes. From the looks of things it shouldn't be hard. The road back to the airport in Seattle is filled with fast food restaurants, waterbed stores and Winnebago dealerships. Every person we pass with a satellite dish in their front yard is a potential customer.

|

copyrightę1995. Contact John Sealander at: john@sealander.com readers since 3/3/96

and

ceramic tile came in one end of this plant and when the dust has settled,

up to eight completely finished three-bedroom homes a day came out the

other. The entire place was a beehive of activity as hundreds of freshly

trained carpenters, welders, cabinet makers, plumbers and electricians

did their best to keep the decibel levels from falling below 120. The

fine dust that permeated the building made it hard to see from one end

of the plant to the other. The smell of sawdust, paint fumes and glue

was overpowering. As we recorded this unusual cacophony of sight and

sound from our perch on the catwalk, it occured to me that I wouldn't

want to trade jobs with anybody working on the floor below.

and

ceramic tile came in one end of this plant and when the dust has settled,

up to eight completely finished three-bedroom homes a day came out the

other. The entire place was a beehive of activity as hundreds of freshly

trained carpenters, welders, cabinet makers, plumbers and electricians

did their best to keep the decibel levels from falling below 120. The

fine dust that permeated the building made it hard to see from one end

of the plant to the other. The smell of sawdust, paint fumes and glue

was overpowering. As we recorded this unusual cacophony of sight and

sound from our perch on the catwalk, it occured to me that I wouldn't

want to trade jobs with anybody working on the floor below.

elses

productivity goals to fruition, but they don't stand a chance. One bad

quarter and they will all be laid off. Watching the beehive of activity

below me, I think about the inordinate amounts of time I spend vacuuming,

gardening, making clumsy plumbing repairs and doing things around the

house, when it would probably be far more productive to hire someone

to do these things for me. I write about how companies should stick

to their core competencies and outsource the rest. But somehow I never

manage to do this myself. I've never have had a maid and probably never

will. This quirk alone will probably keep me from reaching the top of

the ratpile.

elses

productivity goals to fruition, but they don't stand a chance. One bad

quarter and they will all be laid off. Watching the beehive of activity

below me, I think about the inordinate amounts of time I spend vacuuming,

gardening, making clumsy plumbing repairs and doing things around the

house, when it would probably be far more productive to hire someone

to do these things for me. I write about how companies should stick

to their core competencies and outsource the rest. But somehow I never

manage to do this myself. I've never have had a maid and probably never

will. This quirk alone will probably keep me from reaching the top of

the ratpile.